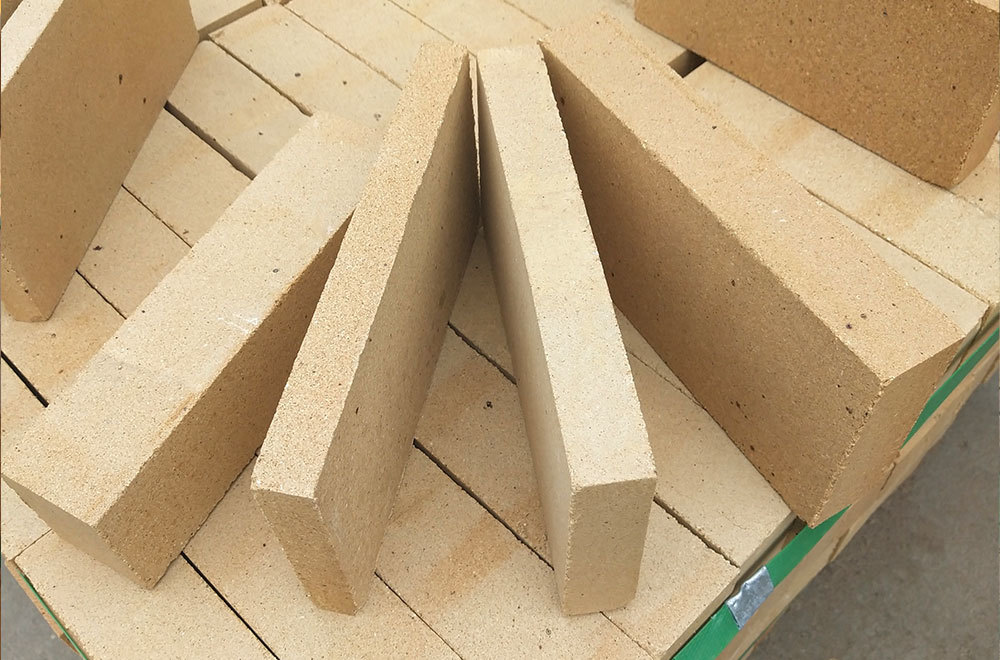

firebrick clay

Refractory soil is a kind of high temperature resistant sandy soil with strong adhesion and fire resistance. It can be used directly with water.

Description

Refractory soil is a kind of high temperature resistant sandy soil with strong adhesion and fire resistance. It can be used directly with water.

A kind of clay that can withstand high temperature. Refractory soil is accumulated on the No. 4 copper smelting shaft furnace workbench found in Tonglushan, Daye, Hubei, with an area of about 4 square meters and a thickness of 8-10 cm. The refractory temperature has been determined: the initial softening temperature is 1301 C, and the melting end temperature is 1370 C. Its chemical composition is: silica 53.68%, ferrous oxide 4.45%, calcium oxide 2.27%, magnesium oxide 0.86%, aluminum oxide 19.43%. The inside of the copper smelting shaft furnace wall is also coated with refractory soil.

Also known as disordered kaolinite. Natural aluminosilicate materials with kaolinite as the main mineral component have a chemical composition of roughly (Al1.8 Fe0.1 Mg0.2) [Si2O5] (OH) 4, Al2O3 content > 30%, refractoriness > 1580 ℃, formed by the weathering of silicate rocks, and are the most basic and commonly used refractory raw materials. Refractory clays used in industry are mainly divided into two categories: hard clays and soft clays. Soft clays are used for good dispersibility and plasticity and are often called bound clays. Hard clay is usually calcined at high temperature and used as brick clinker, and soft clay is directly used as brick binder. Refractory clay is mainly used to manufacture clay, high-alumina refractory bricks, refractory mud and ceramic saggers. For the copper smelting temperature of about 1100 C to 1200 C at that time, this refractory soil is a better refractory material. Coating the inside of the copper shaft furnace with this refractory soil not only ensures the smooth progress of the copper smelting process, but also prolongs the service life of the shaft furnace and ensures the continuous progress of the copper smelting operation. Such refractory soil was produced in the Tonglushan area, and the furnace builders at that time could obtain materials locally, which was very convenient.

Our Strength

Category:

Refractory Soil

Keywords:

Refractories

Related Accessories